Faster production setup

- Wide range of system features improved:

- Semi-automatic strip infeed, strip-width adjustment and strip feed

- Predetermined settings

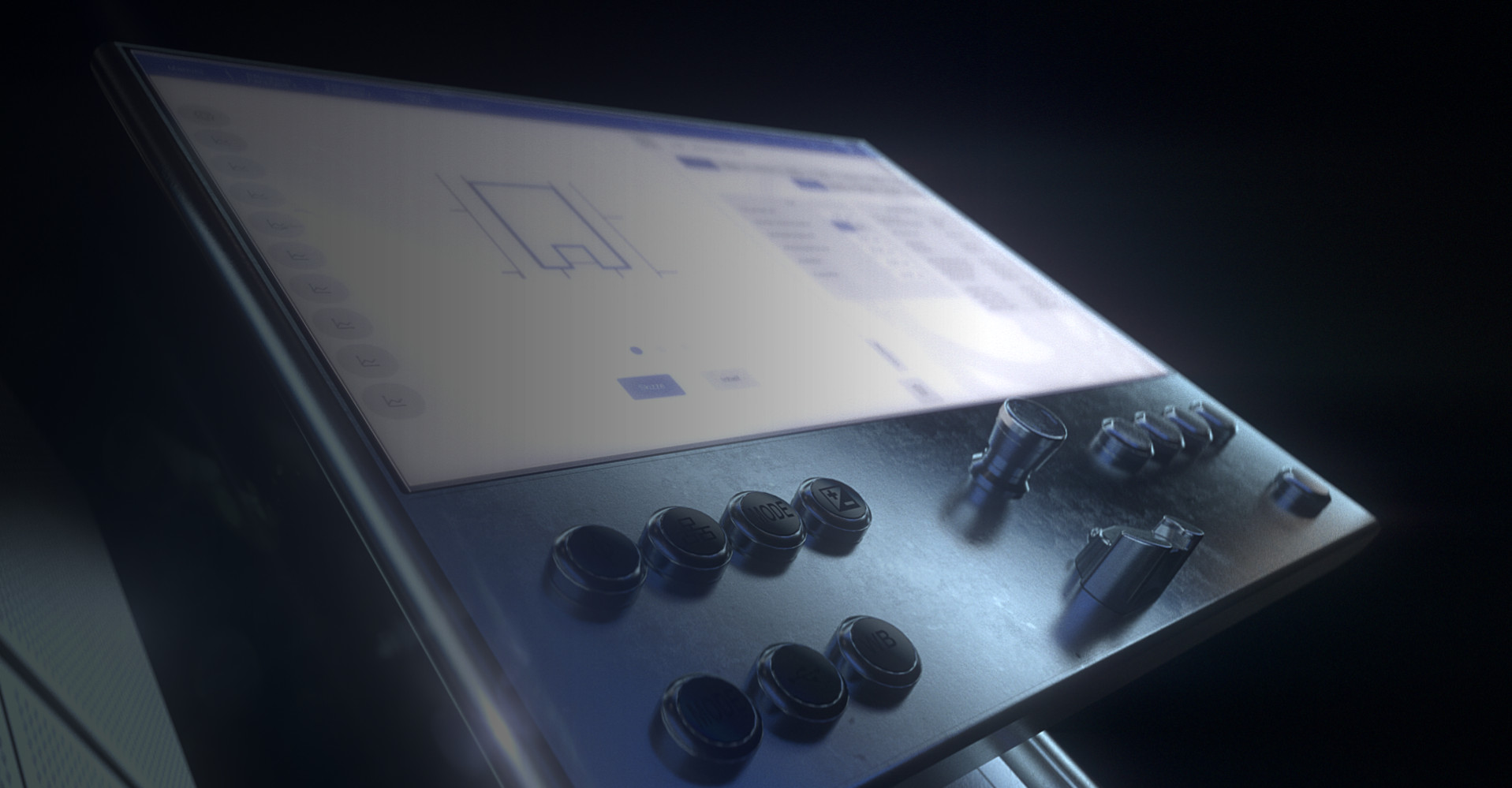

The new FB one is an open solution – in every respect. It is backwards compatible with existing Feintool press tools, offers a wide variety of control options, and integrates seamlessly with digital (Industry 4.0) production control systems. All in all, the FB one delivers superb ergonomics and excellent connectivity.

The FB one can be incorporated easily into existing production environments, and is extremely flexible in terms of tool changeover and setup. It supports condition-based maintenance, and its audit trail function ensures complete visibility into production activities.

Welcome to the new world of fine blanking.

New press design with enhanced functionality.

A variety of technological advancements have significantly streamlined production setup.

Semiautomatic strip feeding, electric strip-width adjustment and the laterally adjustable feeder minimize setup time.

This technology module greatly simplifies setup and reduces the risk of errors.

Condition monitoring is the basis for predictive maintenance and timely, proactive intervention – avoiding repairs and costly downtime.

The latest field-bus technology offers richer functionality and is compatible with Industry 4.0. It allows additional process metrics to be captured, such as press-frame expansion, water flowrate and cooling-system temperature.

The FB one now includes an audit trail function. This provides visibility into all process settings, allowing better, easier compliance with customer quality-assurance requirements.

„The operation of the machine is

economic, simple and easily explained.“

Easier management of tool parameters

Tools are parametrized independently of the press, saving time and minimizing errors in process-data entry and setup. Process parameters are freely programmable. They are checked for plausibility and automatically readjusted in line with changing conditions.

Easy-to-understand error messages

Clearly expressed error messages in plain text provide actionable information for troubleshooting, reducing downtime.

User-friendly help

Operators can enter their own error-specific help text to aid rapid, effective problem resolution.

Freely configurable access rights

Customers can assign access rights based on the user’s role within the organization, minimizing operator and data-entry errors.

Open, Industry 4.0-enabled system architecture

The newly developed FB one control platform can be integrated into an existing corporate network. The software architecture supports man-machine communication. Process and tool data can be exchanged via the corporate network.

Intuitive operation (Visu 3000)

The intuitive, user-friendly multi-touch display means less need for user training and easier operation.