An investment in a better future

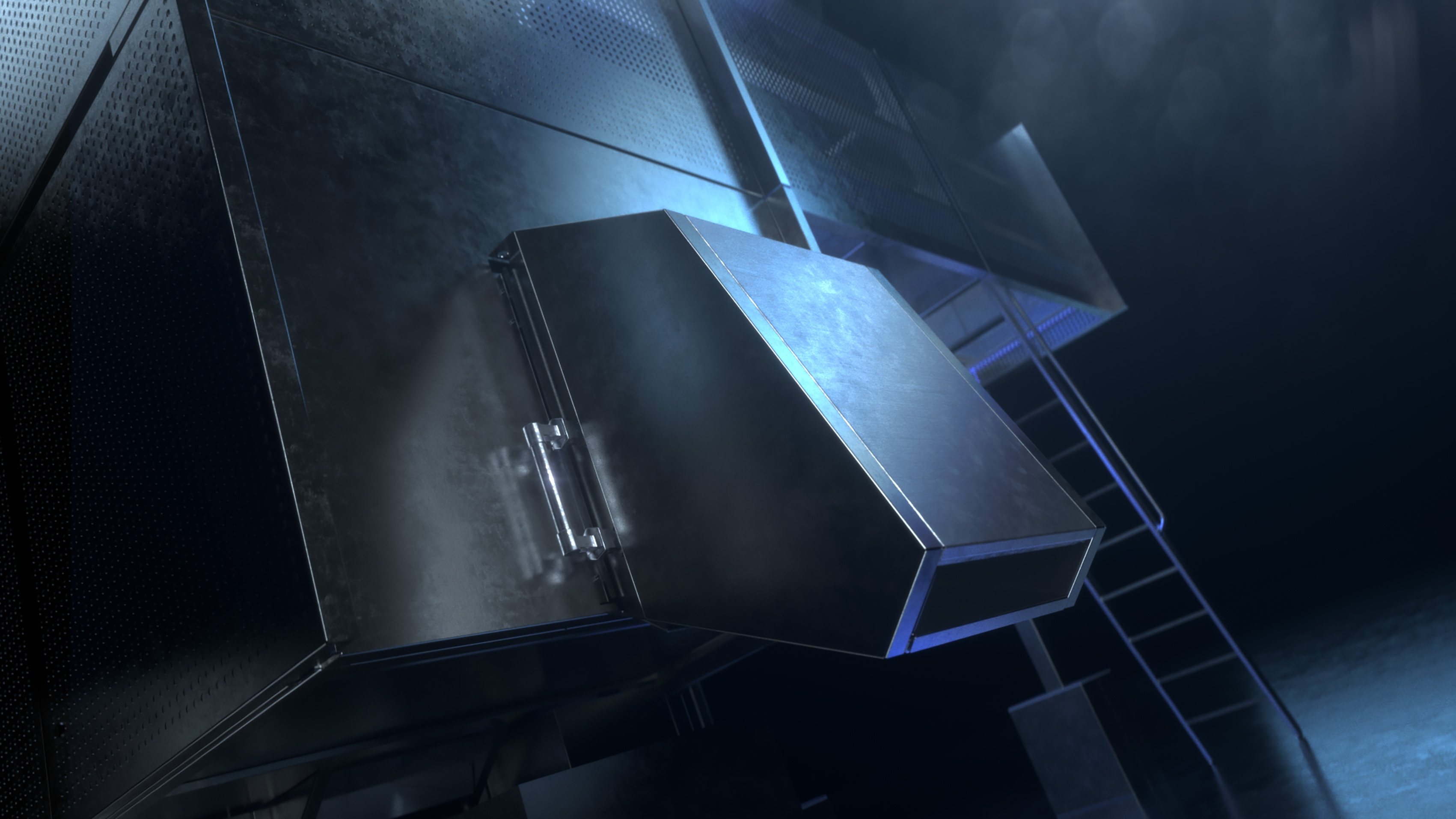

The innovative FB one press streamlines production and raises profitability.

The FB one heralds a new era in fine blanking. It features significant advancements in terms of its hydraulic direct drive, overall design, intuitive control and digital connectivity. And these developments are creating opportunities – for enhanced efficiency in manufacturing, seamless integration with other systems, and entirely new applications.

The FB one’s strengths include greater energy efficiency and eco-friendliness, higher throughput and precision. It enables more complex and larger tools to be used. Its modularity delivers exceptional flexibility. Moreover, the FB one has a more compact footprint, is easier to access, and can be deployed without the need for a foundation pit.

Welcome to the new world of fine blanking.

The FB one delivers robust investment protection.

- The improved hydraulic direct drive includes an additional module that can be configured in line with specific customer needs – redefining the possibilities of fine blanking.

- The FB one enables fine blanking of high-strength and stainless steels to higher quality standards.

- Feintool’s control platform software was purpose-developed in-house. It can be integrated into the existing corporate network, and supports Industry 4.0 objectives.

- The FB one is ergonomic and operator-friendly. It features a configurable user interface for intuitive control and production tracking (audit trail function).

- Expanded, richer functionality for condition monitoring, clearly expressed error messages in plain text, and support for the entry of error-specific help texts.

- The modular layout allows flexible press planning and modification, and requires less space.

- A variety of technical enhancements have facilitated parts and waste management, simplified press retrofits for new production requirements, and ensured backwards compatibility with existing tools.

- The press ensures greater process reliability and reproducibility, reduced wear and tear, and lower maintenance effort and expense.

"We have gone to great measures for the production of the FB One."

Interview with Urs EggenbergerFB one makes fine blanking more cost-effective.

The FB one is built on Feintool’s proven expertise and technology leadership – it is a sound investment in a better future. The FB one is a vital element in the value chain, increasing the profitability of production.

It delivers better results, energy savings, enhanced ergonomics and improved connectivity – and there are additional compelling arguments in the FB one’s favor.

The FB one’s cost-effectiveness is the result of multiple strengths:

- Lower production costs per part

- Enhanced performance and increased stroke rate = greater productivity

- Lower power consumption = increased cost savings

- Smaller ecological footprint

- 50 percent lower oil demand, with fewer oil changes

- Reduced oil aging

- Modular design and component commonality across press families

- Streamlined spare parts management

- Less maintenance, fewer repairs

- High compatibility of tools and components across press families

- Longer tool maintenance intervals

- Faster, simpler tool and coil changeover

- Minimized wear-and-tear

- Longer press service life

- Longer tool service life

- Less downtime = increased availability

- Greater overall equipment efficiency (OEE)

- Faster customer-specific configuration and time-to-delivery

- Excellent value for money